The first written definition of nonwovens came from the American Society for testing and materials in 1962, which defined nonwovens as "textiles made of cotton or fiber webs bonded together by adhesives". At present, The non-woven fabric industry association Inda defines non-woven fabrics as "sheet or mesh structures that wrap fibers or filaments (and perforated films) together by mechanical, thermal or chemical methods. These substrates are flat, perforated plates made directly from a single fiber or molten plastic or plastic film, which are not made by weaving or weaving, and do not need to convert fibers into yarn.

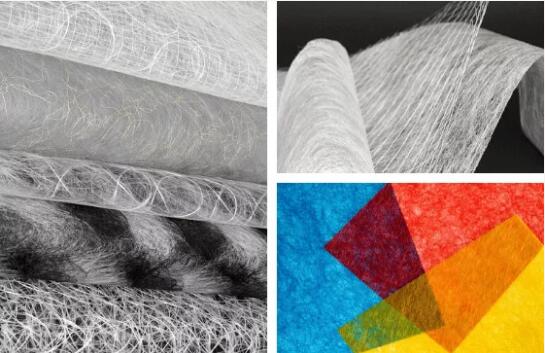

Non woven fabric

The technical definition expresses the basic basis of Nonwovens Technology, but due to the diversity of production technology, the general description of nonwovens is not enough. Like woven or knitted fabrics, each process has its own unique characteristics. There is not much in common except for textile income. Non woven components, for example; Fiber selection, mesh formation, bonding and finishing techniques can be changed to manipulate fabric properties or reverse engineered fabrics according to functional requirements. Due to its achievable characteristics, the nonwovens category has penetrated a wide range of markets, including medical treatment, clothing, automobile, filtration, construction, geotextile and protection.

There are several nonwovens that can be used to make these materials.

The first written definition of nonwovens came from the American Society for testing and materials in 1962, which defined nonwovens as "textiles made of cotton or fiber webs bonded together by adhesives". At present, The non-woven fabric industry association Inda defines non-woven fabrics as "sheet or mesh structures that wrap fibers or filaments (and perforated films) together by mechanical, thermal or chemical methods. These substrates are flat, perforated plates made directly from a single fiber or molten plastic or plastic film, which are not made by weaving or weaving, and do not need to convert fibers into yarn.

Non woven fabric

The technical definition expresses the basic basis of Nonwovens Technology, but due to the diversity of production technology, the general description of nonwovens is not enough. Like woven or knitted fabrics, each process has its own unique characteristics. There is not much in common except for textile income. Non woven components, for example; Fiber selection, mesh formation, bonding and finishing techniques can be changed to manipulate fabric properties or reverse engineered fabrics according to functional requirements. Due to its achievable characteristics, the nonwovens category has penetrated a wide range of markets, including medical treatment, clothing, automobile, filtration, construction, geotextile and protection.

There are several nonwovens that can be used to make these materials.

|